Single Storey Prefabricated House

Product Description

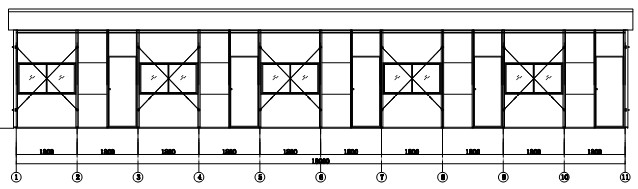

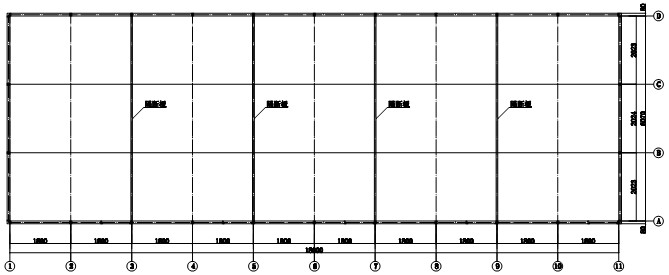

Structural Drawings

Technical Parameters

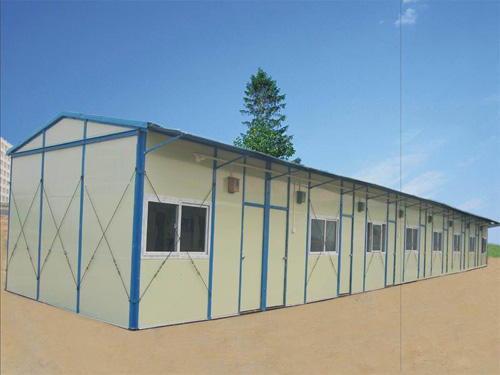

Relevant Pictures

The single storey prefabricated house is economical in environmental protection, and can be easy to assembly and demolition, which achieved the construction concepts of common standardization for temporary building, setting environmental protection & energy saving, rapid and highly efficient building. Prefab house is widely used in remote areas as resident houses, construction accommodations, office, classroom, clinics, oil field camps, offshore accommodation, labor camps, guardrooms, container house and mobile house. The main frame work of prefabricated house is light steel structure and the wall&roof panel is sandwich type. All steel parts are connected by screws.

|

Item

|

Sorts

|

Name

|

K-series single storey | |

|

1

|

products model

|

standardized intensity

|

standardized products,standardized dimension modulus,the production is progressed according to the standardized plan

|

|

|

2

|

removable performance

|

the house can be removed and used repeatedly 8 times in normal usage, and the utilization rate could reach to 98% or more than that

|

||

|

3

|

standard components

|

ground beam

|

C80# steel,the steel which shapes like English word "C" and made of galvanized steel

|

|

|

4

|

upright column

|

C80*40*1.8mm it was jointed into one by two galvanized steel | ||

|

5

|

floor beam

|

the trussed beam was made of welded and galvanized C80# steel

|

||

|

6

|

floor purlin

|

C80# steel,the steel which shapes like English word "C" and made of galvanized steel

|

||

|

7

|

roof beam

|

the purlin was made of square steel tube with the material of Q235,and the surface of the structral member is stain proofing

|

||

|

8

|

roof purlin

|

C80#steel,it was made of galvanized steel

|

||

|

9

|

stairs

|

1000mm steel structure stair was made of welded C160*60*20 steel,and the step was made of 2.5mm figured and galvanized steel plate.

|

||

|

10

|

Corridor panel

|

2.5mm figured and galvanized steel plate.

|

||

|

11

|

wall panel

|

50mm double-faced colored steel sandwich board with the PU,phenolic aldehyde and mineral wool filler inside

|

||

|

12

|

roof panel

|

50mm double-faced colored steel sandwich board

|

||

|

13

|

floor slab

|

15--18mm plywood or 3mm concrete plates

|

||

|

14

|

door

|

steel frame composite wall panel,and the specification is 805mm*2000mm

|

||

|

15

|

window

|

plastic steel sliding window with conch-shaped material,one layer or double layers window

|

||

|

16

|

elective components

|

removable suspended ceiling

|

suspended ceiling made of mineral wool acoustic board

|

|

|

17

|

window

|

colored steel sliding windows’ colors are red,blue or white,the window’s specification is 1740mm*950mm;alnuminium alloy sliding window’s specification is 1740mm*950mm;the window is one layer,double layers; or organic glass.

|

||

|

18

|

door

|

one-way opening door made of colored steel,the specification is 805mm*2000mm;two-way opening door made of colored steel,the specification is 1740mm*2000mm,color can be red,blue or white.

|

||

|

19

|

appliance

|

the plan,design and construction can be provided

|

||

|

20

|

water supply and drainage

|

the plan,design and construction can be provided

|

||

|

21

|

structure

|

roofing load

|

50kg/㎡

|

|

|

22

|

wind resistance

|

11grade,0.6KN/㎡(Chinese standard)

|

||

|

23

|

fire rating

|

the house maintenance material is nonflammable which belongs to B1 level, the plywood of the floor can reach to B1 level if it is fire-proofing.

|

||

|

24

|

seismic fortification intensit

|

7 magnitudes

|

||